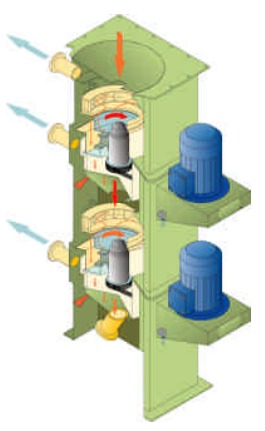

Equipment for reclaiming chemically bonded sand, designed to be compact, and quick and easy to install. All sand reclamation functions are integrated into a single structure.

The reclamation principle is identical to that of the reclamation tower: disaggregation and pre-reclamation on a vibrating screen, grain scrubbing, dedusting, screening, and cooling of the sand. Depending on the type of binder, capacities range from 2 to 4 T/h.

The Sistema de Recuperação Mecânica de Areia begins with lump breaking and pre-reclamation, through friction between the sand lumps and a perforated plate, which separates materials that cannot be reclaimed. The pre-reclaimer is integrated into the Shake-Out unit.

During demolding, if the sand temperature exceeds 200 °C, a sand pre-cooler is required to bring the temperature down to around 100 °C, the ideal range for mechanical reclamation.

After lump breaking, the sand is pneumatically conveyed through pressure vessels to a buffer silo, which feeds the Mechanical Reclamation Tower.

In this tower, the sand grains are cleaned by friction and dedusting. The process includes pneumatic sand cleaning with a special cascading and air-blowing system, which removes dust particles through airflow.

This foundry sand reclamation system relies on attrition between the grains to eliminate and reduce the resin layer that coats them, performing four key operations:

KNBS reclamation systems are suitable for use in all foundries, designed to reclaim chemically bonded sands from all major binding processes.

The intensive sand reclamation process provides much more effective grain cleaning than conventional reclamation systems currently available on the market.

This system is particularly efficient and suitable for reclaiming alkaline phenolic sand, as well as furan and phenolic resins, especially in processes where the sand-to-metal ratio is inevitably high.

This system performs four operations:

1) Lump reduction and sand pre-reclamation

2) High-speed rotary resin removal from sand grains through sand-on-sand impact

3) Classification and dedusting

4) Sand cooling

Thanks to its modular tower-type structure, this system is available in various sizes, ranging from 5 to 20 T/h, and can be supplied with 2 or 3 attrition sections.

The Thermal Regeneration System operates based on the fluidized bed principle.

It includes safety systems for operation with LPG or natural gas, including flame presence monitoring, with a fully automated process and continuous control during operation.

The gas system is monitored by temperature sensors, which perform real-time adjustments to maintain optimized combustion stoichiometry, ensuring minimal gas consumption to keep the system at nominal temperature.

The equipment is designed for the regeneration of foundry sand—typically silica or zircon sand—that has already undergone mechanical reclamation and screening, originating from processes involving organic resin systems such as COLD-BOX, HOT-BOX, NO-BAKE, SHELL, and other resin-bonded aggregates.

The fluidized bed temperature is controlled by an immersion thermocouple, which regulates both the gas flow and sand feed into the bed, maintaining operation within preset limits. The installation includes a gas safety and control system. Additionally, a monitoring system is installed at the base to detect anomalies or irregularities. If any alarm is triggered, the gas supply is automatically shut off. After such an interruption, the system can only be reactivated by authorized personnel.

Due to the characteristics of the fluidized bed system, there are no moving parts in the high-temperature zone. Sand is fed into the furnace through a vibratory feeder or a screw conveyor and follows a predefined path guided by deflector walls, ensuring a sufficient residence time to complete the regeneration process at the required working temperature.

Fume and air extraction is carefully regulated to achieve sand classification, effectively removing fines and dust. The sand is then cooled to a suitable temperature for pneumatic conveying to a silo, from where it is reused for core and mold production.

This system is designed for the regeneration of mixed green sand for core production. The principle of calcination or thermal regeneration through sand grain combustion remains the same; however, additional equipment is integrated into the system to accommodate the composition of this specific “mixed green sand.”

At the system inlet, a “PRO CLAIM” pneumatic reclaimer, manufactured by KNBS under license from SIMPSON, is added. This equipment is essential due to the need to remove bentonite present in the sand.

At the system outlet, a second “PRO CLAIM” or dynamic reclaimer is also added to remove residual bentonite content still present in the sand. After the process, the sand can be used in core production, presenting characteristics similar to new sand.

The separation of chromite and silica sand is achieved through a three-phase system, consisting of rotating drums with permanent magnets and a density separator.