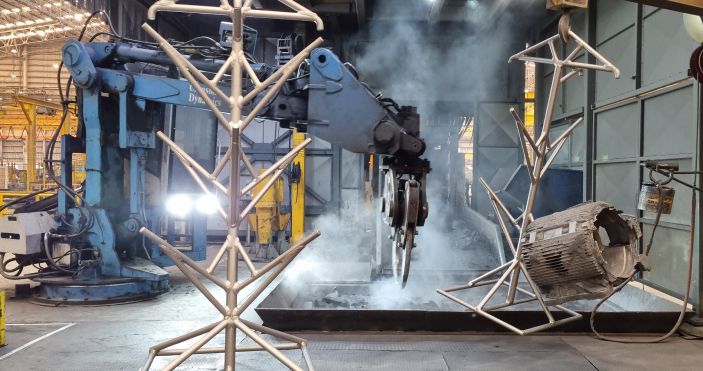

The Shake-Out is built with an extremely robust and technical design, operating with high vibration amplitude and temperature to effectively break down molds from the No-Bake process, reducing them into sand lumps and, eventually, into individual sand grains through friction between particles.

It consists of a reinforced metallic grid, made of electrowelded steel, specifically designed to withstand both vibration and abrasion from the sand. The grid is mounted on a series of steel helical springs, which help absorb vibrations and limit potential resonance peaks or excessive motion.

The vibratory motion is generated by the rotation of vibration cells, which are fitted at each end with two sets of eccentric weights. These weights can only be adjusted when the Shake-Out is stopped.

The vibration cells operate in an oil bath system, and are isolated from direct heat exposure, avoiding temperature-related failures.

The motor is connected to the Shake-Out through a cardan shaft transmission. Below the Shake-Out, a pre-reclaimer is installed, containing a perforated screen with 6 mm diameter holes.

Inside the pre-reclaimer, sand lumps falling through the grid are further reduced in size by mutual friction, until they are smaller than the screen’s hole diameter. The pre-reclaimed sand is then transported through a receiving hopper, mounted above a vibrating conveyor or chute.

Any metal impurities retained by the perforated plate are collected and discharged via a discharge flap, equipped with a pneumatically actuated opening system.

The system is available in a range of sizes and capacities, with grid dimensions starting at 1000×1500 mm up to 6000×4000 mm, and can be modularly combined for very high-capacity installations.

In cases of high sand temperature, a fluidized bed pre-cooler is used, equipped with a water-based heat exchanger connected to an evaporative tower, and mounted directly downstream from the Shake-Out.

The pre-cooled sand can then be pneumatically conveyed to the reclamation system.

This equipment can handle capacities from 1 to 40 tons/hour.

To comply with current regulations regarding occupational health and environmental conditions, all our Shake-Out units can be enclosed in soundproof cabins equipped with dust extraction systems

Access is facilitated by movable doors and roof, which open via hydraulic actuation, making it easier to remove cast parts.